Subscriber Exclusive

Planning a Weaving Project Part 3

You've gotten to the point of knowing what you are weaving and what you are weaving with, here's how to figure out warp length and how much yarn you'll need for your project.

You've gotten to the point of knowing what you are weaving and what you are weaving with, here's how to figure out warp length and how much yarn you'll need for your project. <a href="https://handwovenmagazine.com/planning-a-weaving-project-part-3/">Continue reading.</a>

https://handwovenmagazine.com/cdn-cgi/image/format=auto/https://www.datocms-assets.com/75077/1656680150-allen-jf22-placemats-graves.jpg?auto=format&w=900

This is the third and last installment of “Planning a Weaving Project.” If you need to catch up, check out the other two parts. In the first post, Susan and Melissa talked about narrowing your choices and making decisions about what you want to weave. In the second post, the authors talked about developing a draft and how balance plays a part in many ways. With your plan in mind and your draft figured out, next you need to know how to calculate warp length and the warp and weft yardages you’ll need to weave your project. They start at the end with finishing because it’s an important feature of any project. Enjoy!

Finishes

While planning your project, be sure to consider how you want to finish it. Some finishing techniques, such as twining and hemstitching, take place on the loom; others—such as sufficient nonwoven warp on each end for fringe or enough warp length to allow for areas of plain weave that will become hems—need to be accounted for. If you don’t think about finishing until the weaving is done, you will have limited your options.

SUBSCRIBER EXCLUSIVE

This is the third and last installment of “Planning a Weaving Project.” If you need to catch up, check out the other two parts. In the first post, Susan and Melissa talked about narrowing your choices and making decisions about what you want to weave. In the second post, the authors talked about developing a draft and how balance plays a part in many ways. With your plan in mind and your draft figured out, next you need to know how to calculate warp length and the warp and weft yardages you’ll need to weave your project. They start at the end with finishing because it’s an important feature of any project. Enjoy!

Finishes

While planning your project, be sure to consider how you want to finish it. Some finishing techniques, such as twining and hemstitching, take place on the loom; others—such as sufficient nonwoven warp on each end for fringe or enough warp length to allow for areas of plain weave that will become hems—need to be accounted for. If you don’t think about finishing until the weaving is done, you will have limited your options.

[PAYWALL]

Calculating project length and width on the loom

For most projects, the fabric on the loom will need to be longer and wider than your desired final piece because of draw-in in width and take-up in length on the loom, as well as shrinkage during wet-finishing. Knowing how much to allow for is a challenge because the fiber, weave structure, sett, beat, and wet-finishing all contribute to the change in size. The only way to know for certain is to weave a sample, measure it on the loom, wet-finish it in the same the way you plan to wet-finish the final piece and then calculate the shrinkage rate. If the project’s final dimensions aren’t critical, you can guestimate 10 percent, but don’t be surprised if it’s more or less than that.

Determining warp length

To calculate how long to make your warp, begin with the length of the fabric you want, allowing for shrinkage; we will call that the finished woven length. (If you are weaving multiple pieces, add their lengths.) Multiply this by a factor to allow for take-up. For a typical balanced weave, use 1.1 as your factor, thereby adding 10 percent for take-up and shrinkage. For rep or other warp-faced structures, use a factor of 1.4, meaning you are adding 40 percent. For a weft-faced project you don’t need to add loom take-up, but you may have some off-loom shrinkage.

If your project involves multiple pieces with fringe, add up how much you need to leave between pieces. For most projects, you don’t need to allow fringe before the first piece, because this comes out of the warp used in your header and knots on the apron bar and is part of what is called loom waste. You also don’t need to add length for the fringe after the last piece as this also will usually come out of loom waste. Then add your loom waste. If you don’t know it for the loom you are using, 36" is a safe amount for most looms.

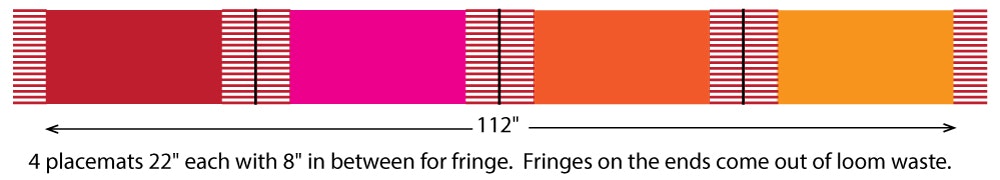

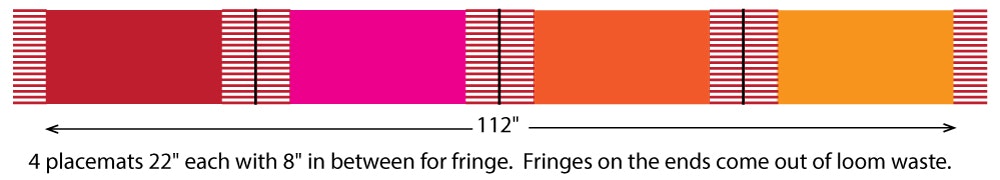

Example: Let’s say you want to weave four placemats with fringe. You want each placemat after wet-finishing and trimming the fringe to be 20" long with 4" fringe on each end. Above is a schematic of what the warp would look like on the loom without any unused loom waste.

Finished woven length of each placemat: 20"

Number of placemats: 4

Total final woven length: 4 x 20" = 80"

Take-up factor of 10 percent: 80" x 1.1 = 88" (22" per placemat)

Allowance for fringe per placemat: 2 x 4" = 8"

Fringe areas between placemats: 3

Allowance for fringe for 4 placemats: 3 x 8"= 24"

Note: Fringe for the first and last placemats will come out of loom waste.

Warp length:

Woven fabric: 88"

Allowance for fringe: 24"

Loom waste: 36"

Warp length: 88" + 24"+ 36" = 148"

To weave these 4 placemats, your warp needs to be 148" long or about 4.11 yd long. Depending on the capability of your warping reel or board, round up if needed.

Calculating yardage requirements

Warp

Multiply the number of warp ends from your draft by the length of your warp as calculated above. Be realistic! If you have calculated a warp of 4.11 yd but you are planning to warp 4.5 yd, use 4.5 in your calculation. If you have multiple colors, use the number of ends in each color multiplied by your warp length. Check your accuracy by adding the results up and comparing them to the yardage you would calculate using only one color.

Weft

Calculating weft yardage requirements requires adding a factor for weft take-up, which happens as the weft travels over and under the warp ends. Generally it will be about 10 percent.

There are 4 components of the weft yardage calculation:

- Width of the warp in the reed or heddle

- Picks per inch (ppi)

- Length of weaving

- Weft take-up: 10 percent or a factor of 1.1.

Multiplying the 4 components will give you an estimate of how much weft you need:

Width x ppi x length x 1.1 = weft yardage needed.

The answer will be in inches so you would then divide by 36 to get the results in yards. And, remember that this is an “estimate” because ppi isn’t always perfect and 10 percent take-up is an educated guess!

Example: Let’s go back to our placemats and pretend we had a width in the reed of 15", with a ppi of 10, and and on-the-loom woven length of 88". The calculation of weft would be: (15" x 10 ppi x 88" x 1.1)/36 = 403 yards.

Again, using multiple colors or different yarns means you’ll have to calculate this for the number of picks of each color or yarn.

Now get out your tablet or graph paper and colored pencils, find some drafts, and get started!