For 50 years, teachers at Yarn Barn of Kansas have seen just about every challenge a beginning weaver might meet. What better way to share this knowledge than with a series of articles about ways to make the process of weaving simple and rewarding? We‘ll begin with this installment about winding a warp using a warping board.

Setting Up Your Warping Board

Warping boards (see photo at top) are a common tool for starting a weaving project. They do three things: they help you measure out a warp of a predetermined length, they make sure all the ends in that warp are the same length, and they put those ends in order. In the United States, most warping boards measure 1 yard horizontally—but mini warping boards and boards that measure in meters are also available, so it’s important to know the peg distance on your board before you begin winding.

The boards can be permanently fastened to a wall, or they can be clamped to a table or sit on an easel. Because straining to reach the pegs on a warping board can become tiring over the course of winding a full warp, make sure the board‘s height is comfortable for you and your shoulders.

Warp length is measured by winding the yarn around a series of pegs on your warping board. To make sure the warp you wind is the right length, you'll start by making a guide string. Measure out a piece of scrap yarn that is the length of your planned warp (for visibility, a color that contrasts with your planned warp is best). The guide string will help you figure out the path your warp should take on the warping board, and it will remind you of that path as you wind.

Plan a Path

If your warp is an even number of yards long and you‘re using a standard warping board, the path your fiber will take back and forth across the full width of the board should be easy to figure out. Here‘s how to get that path set up.

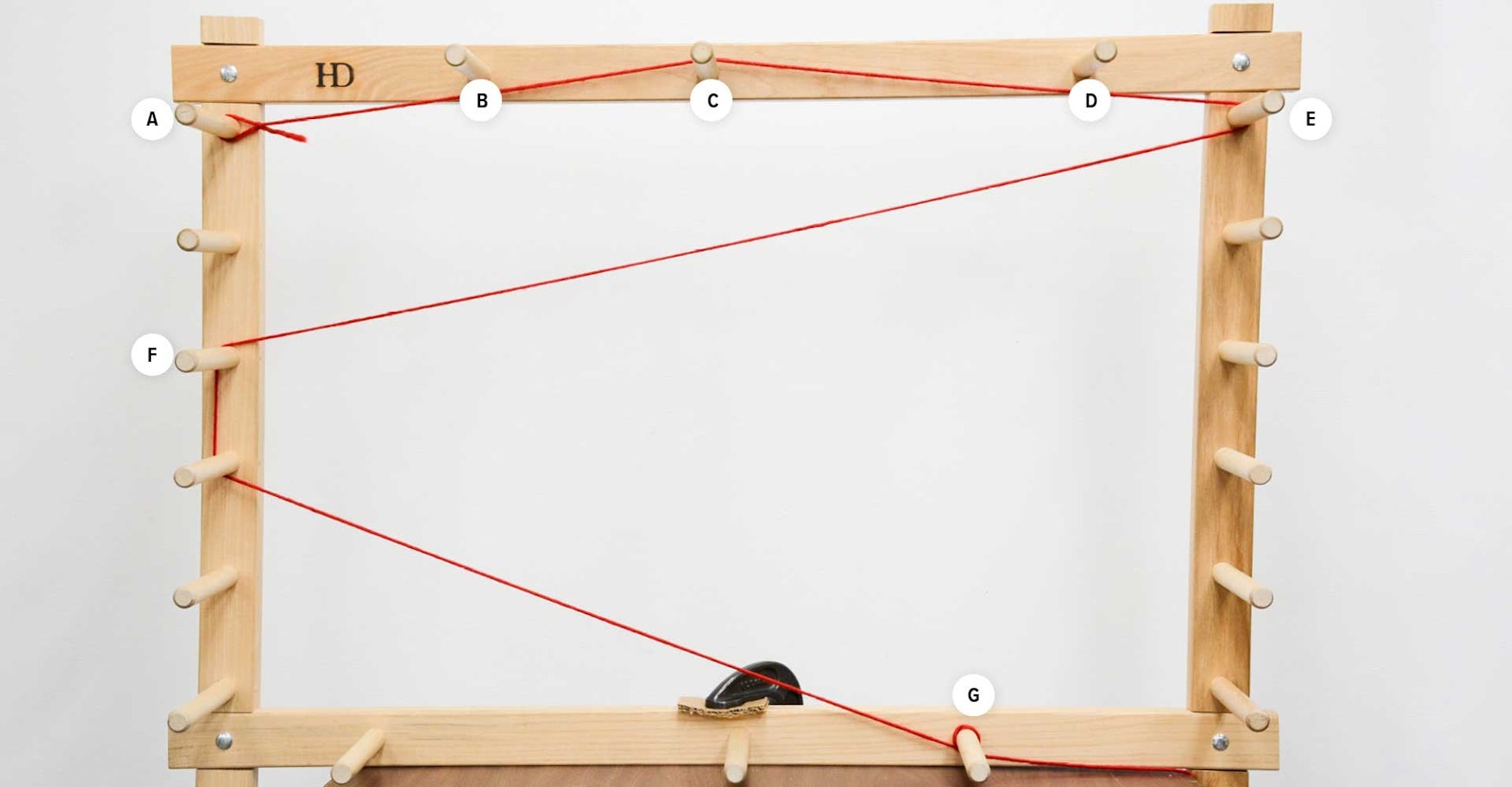

Using the picture below as a reference, put a slip knot on one end of the guide string. Place the loop on peg A and extend the yarn around peg E, travelling over C along the way. Follow a side-to-side path so the guide string ends at a peg. Add a slip knot, and place the loop on the ending peg.

If your warp length includes a fraction of a yard, start by following the same process. Loop the end of your guide string on peg A, but after it travels around peg E, experiment with the path it takes so it ends at a peg. This path might include movement from side to side or along a side, as shown in the photo at the top of this article (it should never double back on itself, though). Add a slip knot on the other end, and slip the loop on the ending peg.

The guide string shows the general path your yarn will follow as you wind your warp, whatever its length. Read on to learn about one minor detour it needs to take along the way.

This 3-yard warp is wound using the full width of the board. It has a porrey cross between C and D—which is more than 12" from the starting peg A.

What‘s a Porrey Cross?

As you wind a warp using your project yarn, you‘ll be making a detour, called a porrey cross, between two of the pegs at the top of your board. When you come to the first porrey cross peg, go over it. When you come to the second one, go under it. Why make a porrey cross? Because it‘s a good way to help you keep track of how many ends you‘ve wound as you go, and it keeps all the warp ends in the right order for when you put the warp on your loom.

The example just above shows a 3-yard warp being wound. For positioning the porrey cross, you pick two pegs on the top rail that are at least 12" from the starting peg A. Tie your project yarn onto peg A, go over C, under D, and then zigzag across and down to the end point G, which is 3 yards from A. Retrace back to A, going over D and under C. You have now measured two warp ends, each of them three yards long. Continue winding your warp until you have the number of ends you need.

As you wind, remember that at the cross you always go over the first peg you come to and under the second peg. When returning to the cross from the other end, you still want to go over the first peg you come to and under the second peg. (Notice that peg B is not used at any point in our example. You won’t always use every peg on a warping board.)

Warping Tips

1: Do not pull the yarn tight as you wrap it around the warping board. Keep the yarn tension consistent—neither saggy nor strained. Stretched yarn risks damaging the board by bending pegs or pulling them out, and it can leave you with a short warp when tension is removed and the yarn returns to its unstretched length.

2: Keep cones and tubes upright on the floor. Use a cone stand if necessary so the yarn unwinds onto the warping board smoothly without tugging on the cones or pegs. Keep yarn balls in a bowl or box and frequently check to make sure they‘re unwinding smoothly.

3: If you need to fix a mistake, carefully wind the yarn back onto the cone or ball peg by peg until you get to the problem. This prevents unnecessary tangling.

MORE: For a print-friendly version of this information, check out the Best Practices eBook. You'll learn next steps as well—including tips for counting, how to wind stripes, removing your warp from the board, threading and sleying, winding on, interpreting drafts, and fixing mistakes.

SUSAN BATEMAN, weaver and teacher, started Yarn Barn 50 years ago. Her hobbies include weaving, working on the farm, volleyball, and bridge.

MELISSA PARSONS has been weaving since 1988. She started working with Susan Bateman at the Yarn Barn in 1992.